The Context

Today’s industry:

● Faces high pressure to reduce operational costs, and yet have high reliability.

● Wants to run more efficiently, waste less and be more considerate towards the environment. The Reality:

● 54% of machine failures are caused by poor lubrication

● Lab oil analysis, being widely practiced is slow and inaccurate

● Absolute or nominal filter ratings are vague and unreliable

● Post installation, it is impossible to evaluate oil quality in real time – forcing a costly premature oil change

We address all these concerns and present a better way to maintain oil health

The Problem with today’s method

● Today oil management is restricted to Filtering and not Cleaning

Filtering – Separation of solids or water from oil

Cleaning – Eliminates the cause of oil oxidation (in addition to contaminant separation)

● Filter units are difficult to evaluate post installation

● Real Time Oil Montitrong is either ignored or not given importance

● Inability to log oil quality data for predictive maintenance

● Particulate Count is not adequate; it is just one parameter- like platelet count of blood.

● Oil replacement periods are decided intuitively, without qualitative evidence

● No quantifiable way to measure oil quality, so cannot say if oil is clean or no!

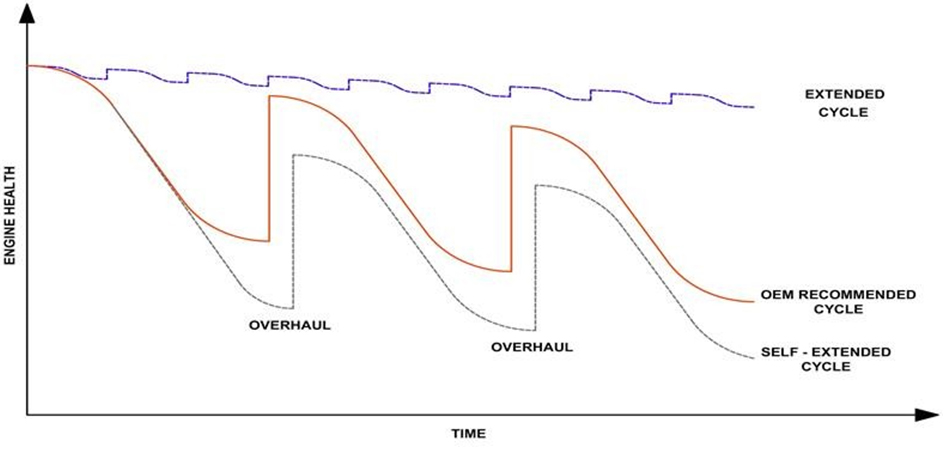

● MTBO may be extended, but overhauls are still needed.

● Breakdowns still occur. System is not foolproof.

Our Vision

To provide customers an accurate and reliable oil condition management system that will:

● Measure and indicate oil quality in real-time

● Remove sources of oxidation and keep the oil continuously clean

● Provide optimal oil replacement period

● Provide detailed oil quality data based on several key oil quality indicators.

● Assist in cost saving by reducing inventory carrying costs

● Increase reliability of filters

● Provide remote accessibility of oil health data

How?

● Through advanced Continuous Oil Quality Management System (OQMS) technology, which is simple and easy to use!

● OQMS technology consists of a Micro filtration system (RRR) and a real-time oil condition monitoring system (Tan Delta)

● RRR filtration system provides absolute filtration till 3μ with ß3 >400 and removes all types of contaminants (including water)

● Tan Delta system will accurately measure and indicate the oil quality in real- time and also provides optimal oil change time

● Both are vastly capable, yet cost-effective

The Ultimate way

● OQMS technology consists of two main pillars:

1. Micro filtration system (RRR)

2. Real-time oil condition monitoring system (Tan Delta)

What

Offering:

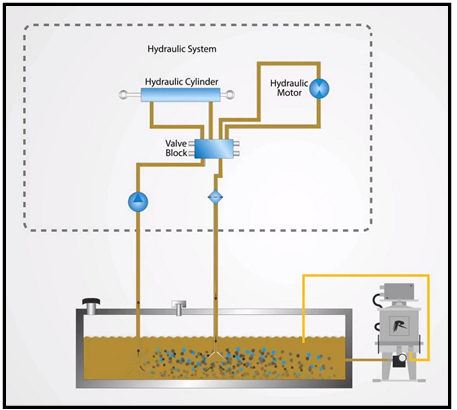

● Unique offline kidney loop bypass oil filtration system, integrated with

an online real-time oil condition monitoring system

● Full-time installation (sale of both)

Belief:

● Without continuously monitoring condition of the oil, simply fitting bypass oil cleaning system does not meet the primary requirement of ensuring oil is always clean and the quality of oil is always a certain

standard.

RRR Micro Filtration

● For the past 40 years, RRR filters have been providing highly efficient filtration systems (β3 > 400), capable of removing water, solid particles, resins, oxidation sludge, varnish and other organic contaminants from oil

● RRR is an offline oil filtration system that employs:

1. Bypass loop (kidney loop) to increase the effectiveness of filtration

2. Depth filtration technology to capture maximum number of contaminants

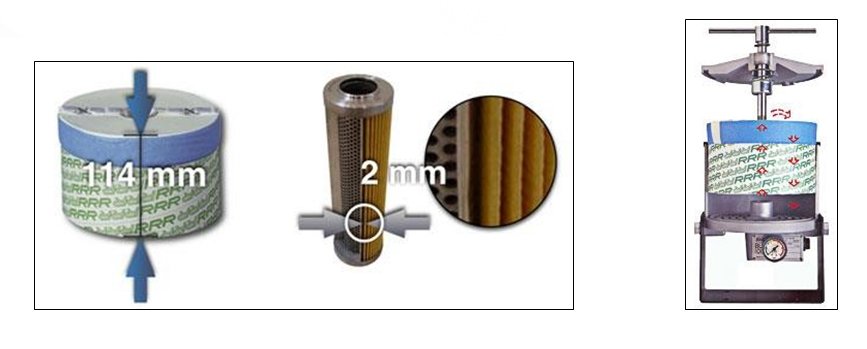

● Due to low pressure and constant flow within the cellulose filter (patented), performance of the system is highly efficient (more than 99.75% of all contaminants greater than 3μ are captured)

Tan Delta Technology

● Tan Delta is a global leader in real-time oil condition monitoring products and solutions.

● Tan Delta employs oil quality sensors (OQSx) to detect oil condition in real-time using patented technology

● Principle of operation:

1. Tan Delta sensor generates an electric field within the oil

2. Ratio of capacitance and conductance of oil is calculated by the sensor

3. This ratio is compared with the Tan Delta oil database and a TDN (Tan Delta Number) is generated

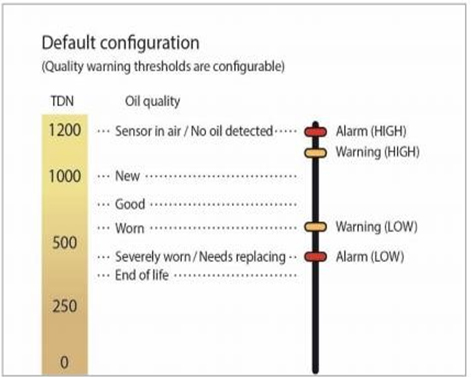

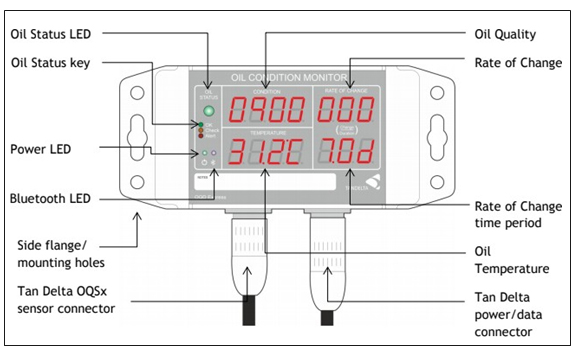

● TDN is a measure of exact oil quality and ranges from 0 to 1200 (higher the better)

What you see: TDN variation

TDN reflects the overall health of the oil on a scale

of 1200 – 0. Higher the number, better is the oil quality

● 1200 – Sensor in air

● 1000 – Fresh sealed oil

● 1000 to 600 – Good oil

● 600 to 300- Worn, replacement needed

● < 300 – Debris of the oil shall cause hampering to the engine (Immediate oil change is required)

Along with TDN, Tan Delta display provides rate of Change of oil quality (ROC) with time and oil temperature.

Mid-Term & Long-Term Benefits

We present a complete, accurate and reliable oil quality management solution, that:

● Purifies the oil continuously upto 3μ with ß3 >400 (99.75% efficiency), along with preventing oil oxidation (results in a minimum of 2x to 5x increase in oil life)

● By clean oil, the overall life of the asset and life of individual components increase substantially.

● Provides accurate real-time oil health data, through multiple output options

● Analyses the performance of filter

● Presents a numerical and visual indication for optimal change of oil along with operator friendly warning signals

● Does not interfere with the performance of machine and hence operator and owner friendly

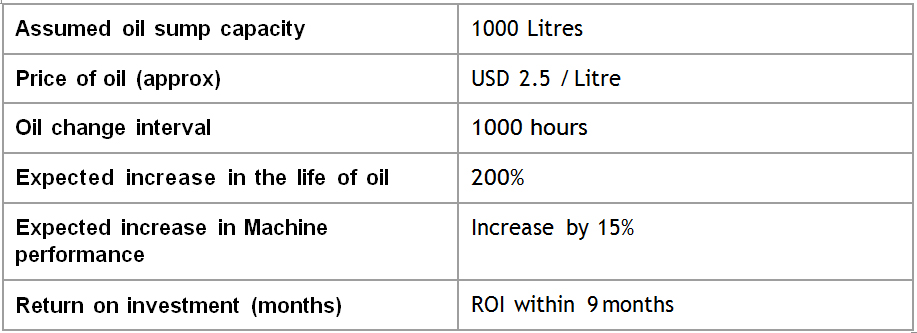

Cost Benefit Analysis

RRR-Bypass Filtration System

● Bypass filtration:

A bypass loop is a circuit that draws oil from oil reservoir and delivers it back to the reservoir after filtration.

● Bypass filtration system enhances efficiency, as it operates on below-mentioned ideal conditions:

1. Reduced flow

2. Minimal pressure and

3. No stress by flow and pressure pulsations.

RRR-Depth Filtration System

Compared to the thickness of other online filters in the order of 2-3 mm, RRR uses a cellulose filter media (patented) that is 114 mm thick. This results in improvement of filtration efficiency and life of filter media.

Tan Delta Technology

● To configure the Tan Delta OQSx sensor, oil profiling is done to correlate TDN with the change in oil parameters

● Such correlated database for 583 oil types is provided by Tan Delta

● Unlike other oil quality sensors, Tan Delta employs Full Scale Holistic (FSH) oil quality data for each specific oil, by incorporating all the below mentioned parameters in TDN:

1. TAN changes (Total acid number)

2. TBN changes (Total base number)

3. Additive depletion

4. Particulate contamination

5. Water ingress

6. Fluids or chemical contamination

7. Viscosity changes

8. Incorrect oil changes

9. Temperature changes

Data Monitoring Options

Tan Delta provides the below-mentioned oil quality data monitoring options:

● Oil Quality Display Express (OQDe)

● Oil Quality Display Professional (OQDp)

● Monitoring on PC or Laptop

● Wireless remote monitoring through Cloud

● Analog (4-20 mA) to a PLC

● MODbus (RS485) and CANbus

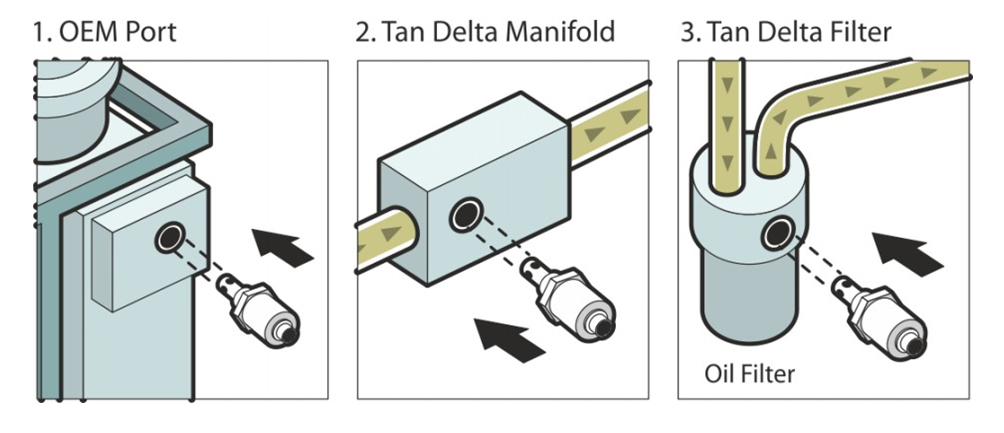

Tan Delta Installation